Industrial Coffee Mill Guide: Boost Performance and Top Quality

In the affordable landscape of coffee manufacturing, picking the appropriate commercial coffee mill plays a crucial role in enhancing both efficiency and item quality. Understanding the nuances of various grinder kinds and vital attributes-- such as adjustable work setups and robust building and construction-- can considerably affect the last taste profile of the coffee.

Comprehending Grinder Types

When selecting an industrial coffee mill, recognizing the numerous kinds offered is vital for enhancing both flavor extraction and operational efficiency. The two key kinds of grinders are blade grinders and burr grinders. Blade mills use sharp blades that chop coffee beans right into inconsistent sizes, leading to irregular removal and potentially unfavorable flavors. While blade mills are usually much more ideal and cost effective for small-scale procedures, they are usually not suggested for industrial usage.

Eventually, picking the best sort of grinder is important to maintaining high quality and effectiveness in coffee production, making it important for services to invest in top notch burr grinders for ideal outcomes.

Key Functions to Take Into Consideration

Choosing a commercial coffee mill requires careful consideration of numerous key functions that can dramatically influence both performance and the total coffee experience. One of the main aspects to examine is the grinding mechanism. Burr grinders are normally liked over blade mills, as they give a consistent grind size, which is vital for optimum removal and taste.

Another important function is the mill's capability. Relying on the quantity of coffee you require to procedure, pick a version that can manage your needs without giving up rate or top quality. In addition, think about the work setups supplied. A functional mill with several setups allows you to customize the work dimension to various developing techniques, enhancing the coffee's taste account.

Evaluate the grinder's sound level, specifically in a hectic coffee shop or manufacturing environment, where excessive sound can be turbulent. Spending in a mill that balances these functions can greatly enhance both operational performance and the quality of the coffee offered.

Optimizing Grinding Process

To achieve the informative post best outcomes in coffee prep work, optimizing the grinding procedure is essential. The work size significantly affects removal, flavor, and general high quality of the made coffee.

Additionally, keeping an eye on the grinding rate can maximize the procedure. Slower grinding usually produces less heat, preserving delicate flavors and fragrances. Alternatively, much faster grinding might create excessive heat, negatively impacting the coffee's quality.

Upkeep and Treatment Tips

Correct upkeep and care of industrial coffee mills are essential for ensuring optimal efficiency and long life. Routine cleaning is the foundation of maintenance; deposit build-up can impact flavor and grinding efficiency. It is recommended to clean up the grinder after each usage, cleaning down the exterior and getting rid of any kind of coffee premises from the burrs.

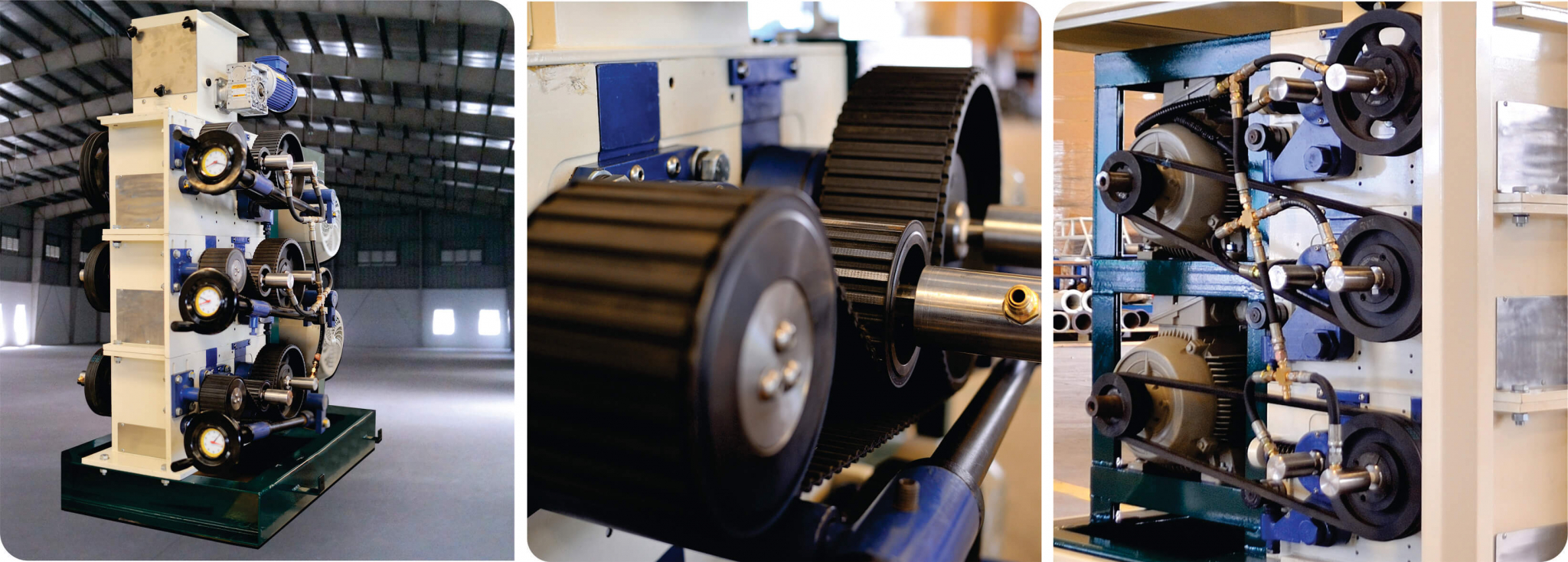

Additionally, inspect the grinding burrs for damage. Boring burrs can compromise work consistency, so they should be changed as needed. Industrial Coffee Grinder. Periodically adjusting the mill is likewise important, as this maintains the wanted grind dimension for different brewing approaches

Lubrication of moving components must be executed according to the supplier's specs, as this reduces rubbing and prolongs the life of the tools. It is important to make use of food-grade lubricants to ensure security and compliance with wellness guidelines.

Last but not least, keep the mill in a secure and dry atmosphere to avoid corrosion and rust. By sticking to these maintenance and care pointers, operators can improve the performance why not try these out of their industrial coffee mills while guaranteeing high-quality outcome and prolonged functional life.

Roi Analysis

Examining the return on financial investment (ROI) for industrial coffee grinders is critical for businesses seeking to enhance their coffee production capacities. A complete ROI evaluation aids establish the financial viability of investing in top notch mills, enabling organizations to moved here consider the first costs against potential gains.

Assess the acquisition cost of the grinder, consisting of setup and any kind of required modifications to existing framework. High-performance grinders often lead to lowered grinding time and boosted throughput, which can considerably improve performance.

In addition, consider the effect on item high quality. Industrial Coffee Grinder. Superior grinders produce an even more consistent grind dimension, which can enhance taste profiles and consumer complete satisfaction, ultimately driving sales. By raising the high quality of the end product, organizations can justify greater pricing, causing increased profits

Conclusion

In summary, a commercial coffee grinder plays an essential function in improving both effectiveness and item top quality within coffee manufacturing. Inevitably, the critical financial investment in a trusted mill adds dramatically to boosted earnings and competition in the coffee market.

In the competitive landscape of coffee production, selecting the right commercial coffee mill plays a crucial role in enhancing both efficiency and product top quality. The 2 primary types of mills are blade mills and burr grinders. Within the burr grinder group, there are level burr mills and conelike burr grinders, each with its advantages. Burr mills are normally favored over blade grinders, as they provide a regular grind size, which is critical for optimum extraction and taste.

In recap, an industrial coffee mill plays an essential function in boosting both effectiveness and item quality within coffee production.